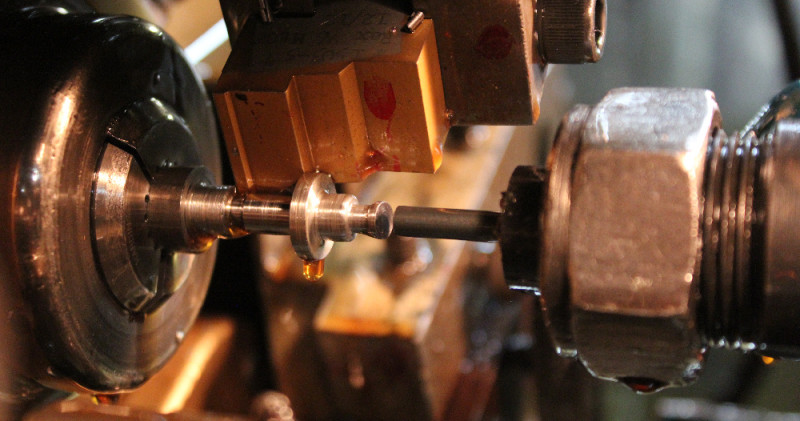

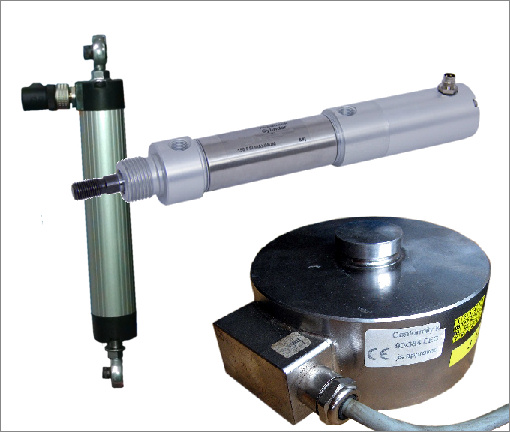

While other systems use physical stops and air-pressure to sense a feed issue, the Inspector uses an electrically-isolated probe or cutting tool to sense the end of the part. To prevent false positive sensing, the system is only satisfied if the probe is made simultaneously with an adjustable cam set to the exact point in the cycle when the probe should be made. All cams and probe also must change-state each cycle to verify proper setup and function.

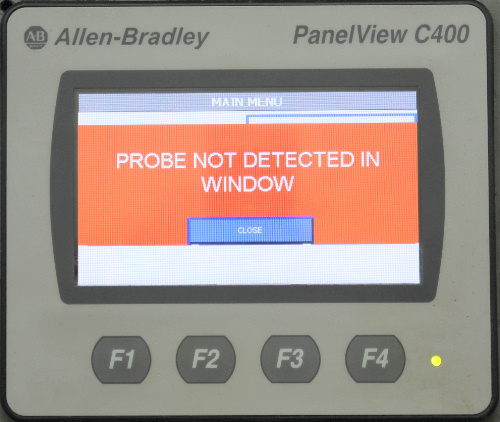

4″ Color Touchscreen Interface

Easy-to-read display for setup of machine and diagnostic readout. Industry-Standard quality hardware ensures reliable operation and easy sourcing for replacement parts.

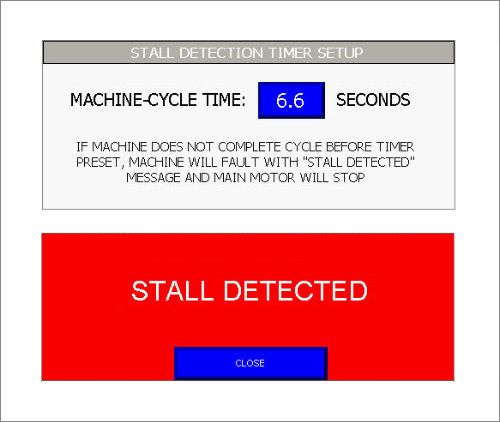

Protection from costly and dangerous stall-conditions

If the machine-clutch is engaged, and motion is not seen by the Inspector for a preset-number of seconds, the machine will shutdown and display the fault shown above.

Visual and Audible Notification

A flashing red light and warning siren allows your operators to know from a distance when your machine has stopped for some reason.

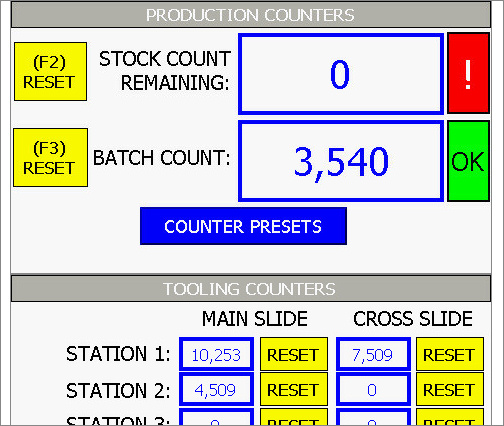

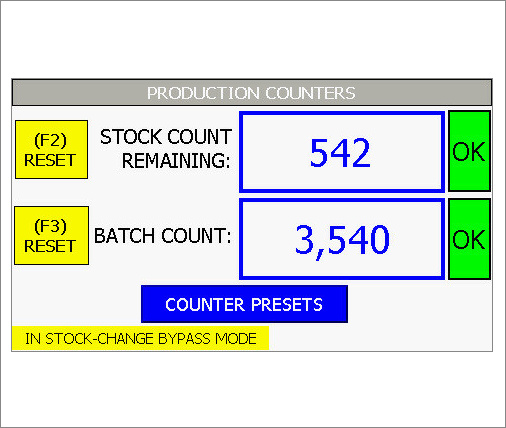

Stock / Batch / Maintenance Counters

The Inspector will stop your machine when stock / batch / tooling counters are exceeded, and display a message.

Stock-Change Auto-Stop & Bypass

Each time the stock-counter is reset, the machine will cycle once then automatically stop for each spindle to be reloaded. After loading all spindles, the Inspector will automatically disable the probe for the first cycle of each spindle, and re-enable itself for the remainder of the run.

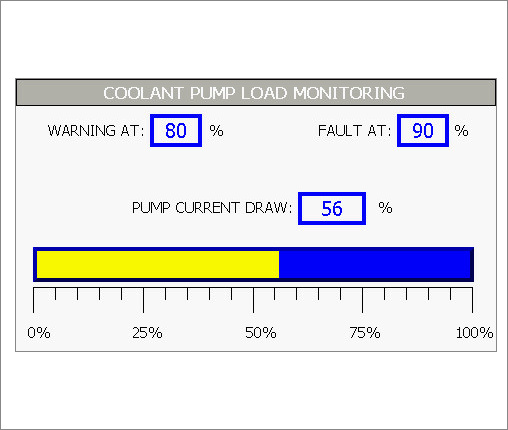

Pump and Main Motor Load Monitoring

Monitor the current-draw of your coolant-pump and main-motor to alert the operator to machine-issues or clogged-pump screens. A warning is displayed on the screen when current-draw exceeds the WARNING setpoint and the machine will stop when current exceeds the FAULT setpoint.

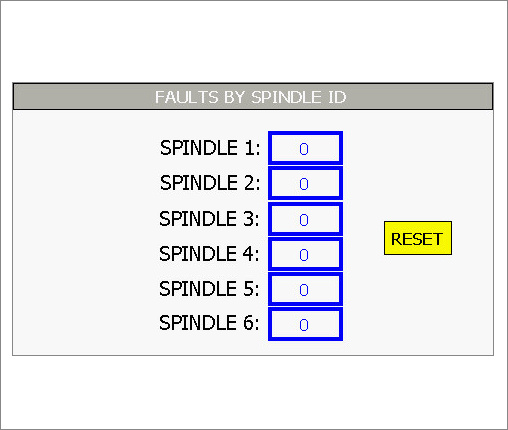

Track Short-Feed Fault by Spindle ID

The Inspector can track faults by spindle-number to show patterns and help diagnose issues on individual spindles which may not be easily recognizable otherwise.

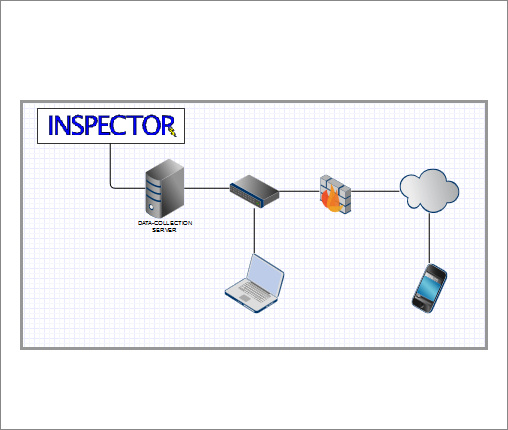

Local and Mobile Remote Monitoring

With the addition of a data-collection server, the Inspector can be monitored from any computer in your plant or even on your mobile device. Verify production is running from the comfort of your home!

Auxiliary Equipment Monitoring

The Inspector can monitor 24v or 110v digital signals in addition to 0-10v or 4-20mA analog signals during the machining cycle. We can even delay or prevent main-motor start depending on auxiliary signal status to prevent damage to equipment. The Inspector is very adaptable, and FORCE can customize a system to monitor the signals you need.