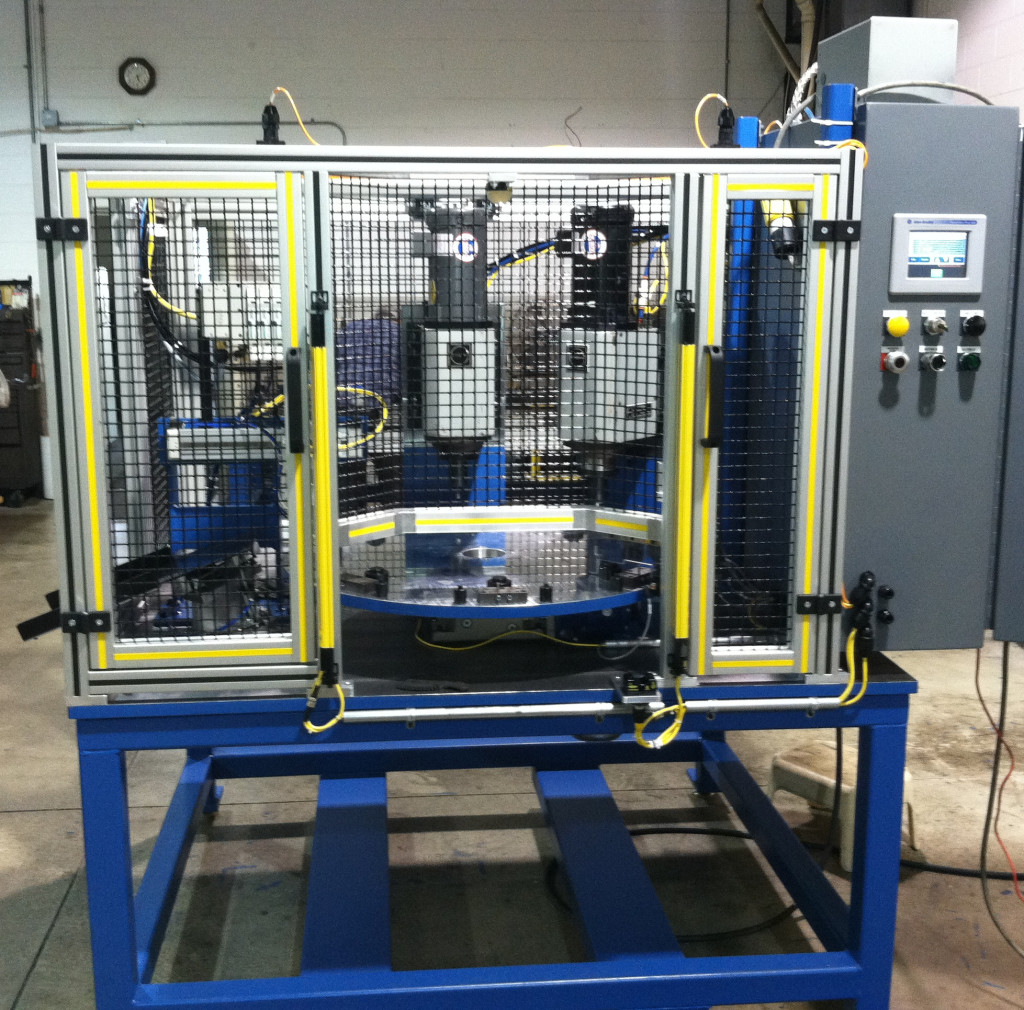

8-Station dual orbital-riveting machine with motor-current monitoring and automatic unloader with pass/fail chute

Mode Control ( Auto / Manual / None )

- AUTOMATIC MODE – Normal operating mode for production employees. No manual functions are enabled, requiring part to be processed through machine in the intended controlled manner.

- MANUAL MODE – Intended for maintenance personnel, this allows manual operation of individual aspects of the machine. Particularly useful in testing inputs and outputs for troubleshooting purposes.

- NO MODE – In this mode, machine will not function. All outputs are disabled in software.

Maintenance Functions

- I/O Page on HMI for visual indication of all Inputs and Outputs

- Verbose faults and alarms on HMI for easy troubleshooting

- Total Machine Count (non-resetting) for maintenance-count reference

FORCE Machine-Design Basics

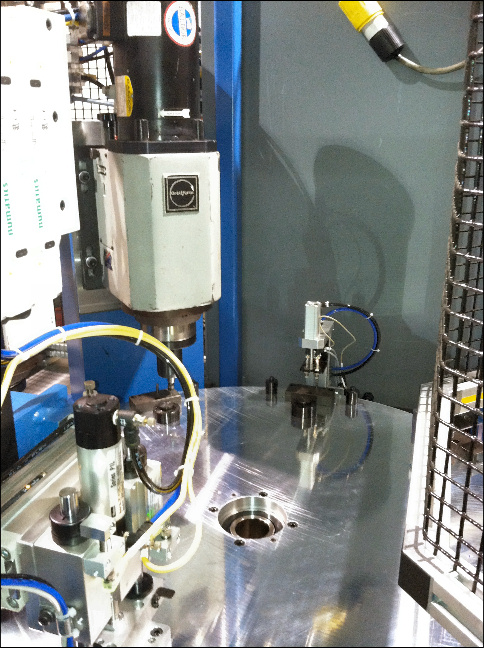

- Hard-fixturing provides the easiest way to prevent incorrectly loaded or parts with missing features.

- If changeover is required, verification of correct changeover performed by sensors before automatic-mode is allowed.

- Optionally, border-samples (red-parts) can be required to be run through machine each shift.

- Primarily use simple digital proximity-switch based probes, only using more complex sensors or vision when absolutely necessary. Keeping things simple keep the machine easily maintained and reliable.

- Automatically unload parts leaving it to the machine – not the operator – to decide the final disposition of a finished part.

- If the operator must unload the part, require a supervisor with a key to allow a bad-part to be removed from the machine.

Machine Networking & Monitoring

FORCE designs and programs machines with the ability for future data-collection & monitoring. We have the capabilities to develop custom software for your application.

- Whether you want to view the status of your machine from across the plant or world, FORCE can provide a solution.

- Process-data can be captured and analyzed for export into Office applications, as well as integrated into or used alongside existing ERP systems.

- Traceability information such as serial-numbers, test results, or operator-information can be stored into a database and retrieved via web-interface or other means.

Counter-clockwise from rear: changeover-verification & part-presence station, followed by orbital riveting station. Unloader in foreground.